- Home

- Spring products

- Coiled Wave Springs (CWS)

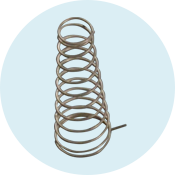

Coiled Wave Springs (CWS)

What are Coiled Wave Springs?

Coiled Wave Springs (CWS) are made by coiling flat wire material while giving it a continuous wave shape, and are particularly effective for static load applications. When compressed, they are characterized by nearly parallel deflection and the ability to exert a large spring force in a limited space.

Strengths of Coiled Wave Springs

When trying to obtain a large spring force using a typical cylindrical compression coil spring, the size and strength of the spring itself may become larger than necessary. In contrast, Coiled Wave Springs (CWS) can increase the spring force while suppressing the increase in size of the spring itself. This allows the material and shape to be smaller than compression coil springs, leading to space savings and weight reduction. Benefits of replacing compression coil springs Coiled Wave Springs (CWS) contribute to "space savings" and "weight reduction" compared to compression coil springs.

This allows the material and shape to be smaller than

compression coil springs, leading to space savings and

weight reduction.

Benefits of replacing compression coil springs

Coiled Wave Springs (CWS) contribute to "space savings" and "weight reduction" compared to compression coil springs.