- Home

- Medical Devices and Components

- Torque Coils

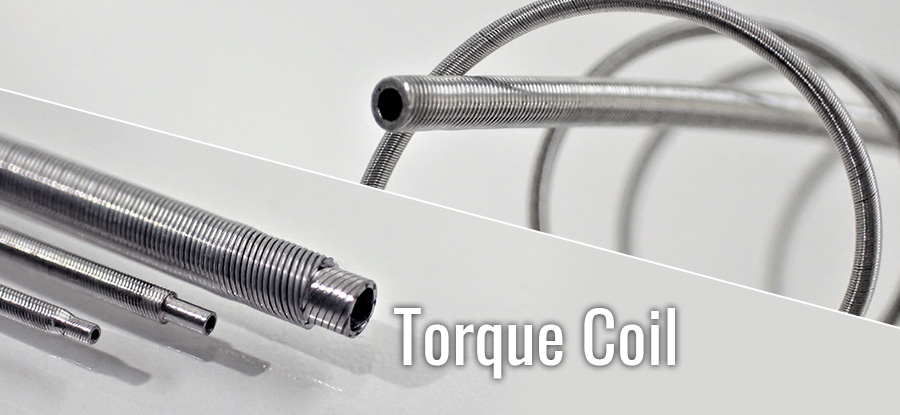

Torque Coils

What are Torque Coils?

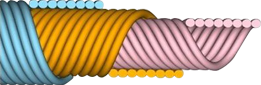

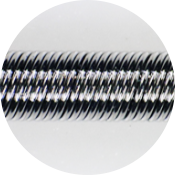

Torque coils are made by coiling several strands of wire as thin as a hair and layering them in three layers.

This technology achieves excellent rotational synchronization with little irregularity despite the long length of the coils.

Rotational Synchronization movie

A coil inserted in a sheath is placed in a hoop shape and rotated by connecting one end to a motor. Even in the twisted hoop state, you can observe that the marks at both ends of the coil rotate synchronously.

Standard Processing Range

| Structure | Multilayered Winding (3 layor, 2 layor) |

|---|---|

| Inside Diameter | 0.2mm-1.5mm |

| Outer Diameter | 0.4mm-3.0mm |

| Element Wire Diameter | Min. 0.02mm |

| Coil Length | Max. 3,000mm |

Processing Examples

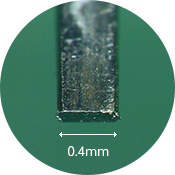

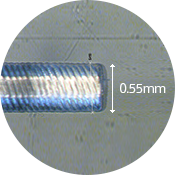

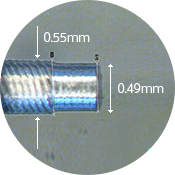

Support for Round wires, Flat wires

Wire Diameter φ0.05

Wire Diameter φ0.05 Wire Width w0.05

Wire Width w0.05

Brazing / Grinding

The coil ends can be finely brazed and machined, including processes such as grinding, on the end face of the coil.

Before Grinding

Before Grinding After Grinding

After Grinding

Rolling Process

In-house rolling from a round wire to a flat one is also available.

We can process a minimum thickness of 0.02mm and thickness : width = 1:5.

Engineering Application

- Ultrasound endoscopic instruments (IVUS, OCT, high-frequency probes, etc.)

- Endoscopic instruments (forceps, snare, high-frequency knife, etc.)

- Catheters