Stents

What is a stent?

* It is a nickel-titanium metal component that is implanted in tubular areas of the body, such as blood vessels and the colon. The stent can be implanted to physically widen passages to address constrictions and blockages.

Braiding Wires, Cutting Laser Tubings

Domestic stents (manufactured in-house) are also supplied on a made-to-order basis. Please contact us for materials other than nickel-titanium.

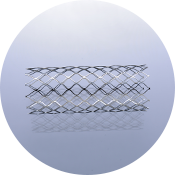

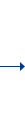

Braided Stents

Nickel-titanium wires braided in-house to the size you specify and the design you require.

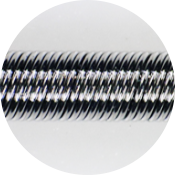

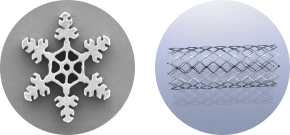

X-Ray Opaque Marker Coils

We can also manufacture + assemble X-ray opaque marker coils using our spring processing technology.

Please contact us for marker coils for catheters as well as stents.

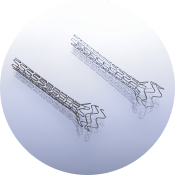

Laser Cut Stents

Nickel-titanium tubing is laser cut and expanded to your specifications. Through our overseas subsidiaries, we can also procure specialty alloy tubing which can be difficult to obtain locally.

Finish process (Electro Polishing)

What is Electropolishing?

Electropolishing smooths metal surfaces and edges by electrolysis. This results in the reduction of surface irregularities.

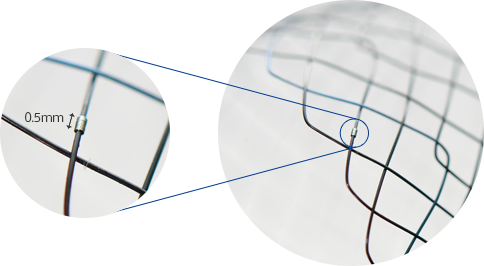

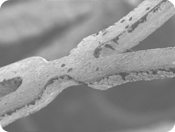

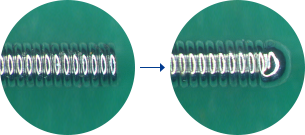

Before Electropolishing

After Electropolishing

Effects of Electropolishing

The beneficial effects of electropolishing for medical devices include:

- Removal of small burrs

Makes micron-level deburring possible. - Formation of passive film

Improves corrosion resistance. - Removal of oxidised film

Contributes to electrical conductivity - Prevention of metal fatigue

Improves durability.

Electro Polishing Applicable Metals

- Nitinol example : Laser Cut Stents

- Stainless Steel

- CoCr

- Titanium

Laser Processing

What is laser Processing?

Laser processing uses laser energy for precision cutting, welding, marking and many other manufacturing-related process.

Laser Processing Examples

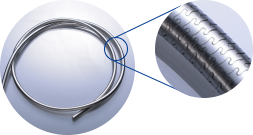

Laser Cutting; Thin Sheet, Tubing

Fine cuts in straight tubing introduces flexibility.

Laser Welding, Spherical Surface Process

Laser Welding

Spherical Surface Process

Marking

Advantages of Laser Process

- Thin sheet metal processing is possible.

- Beautiful cut cross-sections

- Fine machining is possible.

- Not dependent on the hardness of the metal

Standard Processing range

| Materials | Ni-Ti, Ni, SUS, Ti, PT, CoCr etc. |

|---|---|

| Thickness | 0.05mm-3.0mm |

| Minimum width of cut slit | -1,500mm |

| Shape | Tubing, Thin plate |